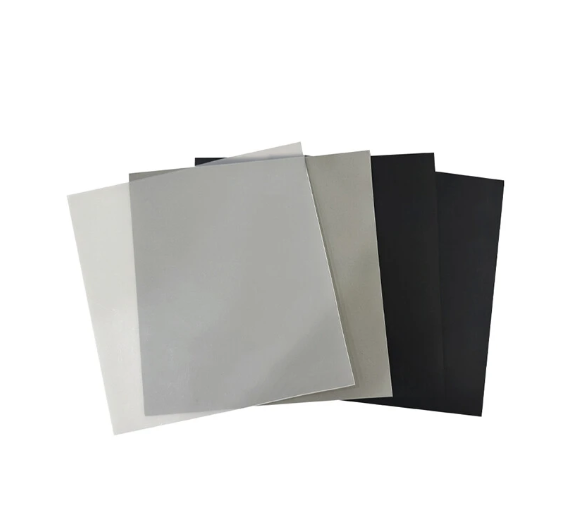

# High Density Polyethylene Geomembrane: Properties and Applications in Environmental Engineering

## Introduction

High Density Polyethylene (HDPE) geomembranes have become an essential component in modern environmental engineering projects. These synthetic membranes offer a reliable and cost-effective solution for various containment applications. In this article, we’ll explore the properties of HDPE geomembranes and their diverse applications in environmental engineering.

## Properties of HDPE Geomembranes

### 1. Durability

HDPE geomembranes are known for their exceptional durability. They can withstand harsh environmental conditions, including UV exposure, chemical attacks, and temperature fluctuations. This makes them ideal for long-term applications in various environmental projects.

### 2. Chemical Resistance

One of the most significant advantages of HDPE geomembranes is their excellent chemical resistance. They can resist a wide range of chemicals, including acids, alkalis, and organic solvents, making them suitable for use in hazardous waste containment and industrial applications.

### 3. Low Permeability

HDPE geomembranes have extremely low permeability, which makes them highly effective as barriers against liquid and gas migration. This property is crucial in applications such as landfill liners and pond liners, where preventing leakage is paramount.

### 4. Flexibility

Despite their high density, HDPE geomembranes maintain a degree of flexibility. This allows them to accommodate ground movements and settling without compromising their integrity, ensuring long-term performance in various environmental conditions.

## Applications in Environmental Engineering

### 1. Landfill Liners and Caps

HDPE geomembranes are widely used as primary and secondary liners in modern landfill systems. They prevent leachate from contaminating groundwater and help contain landfill gases. Additionally, they are used as caps to prevent water infiltration and control gas emissions.

### 2. Water Containment

In water management projects, HDPE geomembranes are used for lining reservoirs, ponds, and canals. Their impermeability ensures efficient water storage and prevents seepage, making them valuable in both agricultural and municipal water management systems.

### 3. Mining Applications

The mining industry extensively uses HDPE geomembranes for heap leach pads, tailings ponds, and process water containment. Their chemical resistance and durability make them ideal for handling the harsh conditions and corrosive materials often encountered in mining operations.

### 4. Wastewater Treatment

HDPE geomembranes play a crucial role in wastewater treatment facilities. They are used to line anaerobic lagoons, aeration basins, and sludge storage areas, preventing contamination of surrounding soil and groundwater.

### 5. Aquaculture

In the aquaculture industry, HDPE geomembranes are used to line fish ponds and shrimp farms. They provide a clean and controlled environment for aquatic life while preventing water loss and contamination.

## Installation and Quality Control

Proper installation is crucial for the effectiveness of HDPE geomembranes. The process typically involves:

1. Subgrade preparation

2. Panel deployment

3. Seaming using thermal or chemical methods

4. Quality control testing, including destructive and non-destructive tests

Regular inspections and maintenance are essential to ensure the long-term performance of HDPE geomembrane installations.

## Conclusion

High Density Polyethylene geomembranes have revolutionized environmental engineering with their unique combination of properties. Their durability, chemical resistance, and low permeability make them indispensable in various applications, from waste containment to water management. As environmental regulations become more stringent and the need for sustainable solutions grows, HDPE geomembranes will continue to play a vital role in protecting our environment and natural resources.